Stainless Steel

• Unmatched Durability: Stainless steel strut channels and accessories offer exceptional strength and longevity, ensuring your installations withstand the test of time.

• Superior Corrosion Resistance: Engineered to resist rust and corrosion, these components maintain their integrity even in the harshest environments, reducing maintenance costs.

• Aesthetic Excellence: With a sleek, professional appearance, stainless steel enhances the visual appeal of your projects, reflecting a commitment to quality and precision.

Advantages of Stainless Steel Strut Channels and Accessories

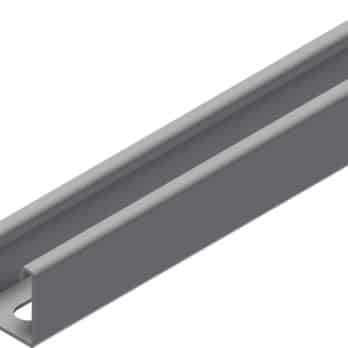

Strut channels are indispensable in construction and industrial projects, providing structural support for electrical conduits, piping, and mechanical systems. These channels come in various materials, including hot-dip galvanized (HDG), pre-galvanized, and stainless steel—each offering unique characteristics. This article explores the advantages of stainless steel strut channels and accessories, highlighting why they outperform HDG and pre-galvanized options.

Understanding Strut Channel Materials

Hot-Dip Galvanized (HDG)

- Definition and Process:

HDG channels are manufactured by immersing steel in molten zinc, forming a thick, protective coating that shields against corrosion.

- Applications and Benefits:

Commonly used in outdoor settings, HDG channels offer better corrosion resistance than pre-galvanized options.

Pre-Galvanized

- Definition and Process:

Pre-galvanized channels are zinc-coated before fabrication, resulting in a thinner layer of protection.

- Applications and Benefits:

Best suited for indoor applications with limited exposure to moisture, pre-galvanized channels are cost-effective but less durable than HDG.

Stainless Steel

- Definition and Process:

Stainless steel channels are made from steel alloys containing chromium. This element creates a passive chromium oxide layer that effectively prevents corrosion.

- Applications and Benefits:

Ideal for demanding environments, stainless steel excels in settings requiring high durability, corrosion resistance, and hygiene, such as food processing and pharmaceutical facilities.

Advantages of Stainless Steel Over HDG and Pre-Galvanized

- Corrosion Resistance

Stainless steel’s exceptional resistance to corrosion makes it ideal for environments where HDG and pre-galvanized materials may deteriorate over time.

- Durability and Longevity

Its extended lifespan and reduced maintenance needs translate into significant cost savings, making stainless steel a reliable long-term investment.

- Aesthetic Appeal

The polished and modern look of stainless steel is favoured for applications where visual impact matters, such as architectural installations.

- Hygiene and Cleanliness

Thanks to its non-porous surface, stainless steel is easy to clean and maintain, making it perfect for areas with strict sanitation requirements, like food processing plants.

- Strength and Load-Bearing Capacity

Known for its robust structural integrity, stainless steel is highly suitable for applications that demand superior strength and reliability.

Ideal Environments for Stainless Steel Strut Channels

- Marine and Coastal Areas:

Its resistance to saltwater corrosion makes stainless steel perfect for coastal infrastructure and offshore installations.

- Chemical and Industrial Plants:

Stainless steel’s ability to endure exposure to harsh chemicals ensures longevity in industrial applications.

- Food Processing and Pharmaceutical Industries:

With its compliance with strict hygiene standards and resistance to corrosive cleaning agents, stainless steel is well-suited for cleanroom environments.

- Outdoor Installations:

Stainless steel withstands diverse weather conditions, making it an excellent choice for durable outdoor applications.

Common Stainless Steel Strut Channel Accessories

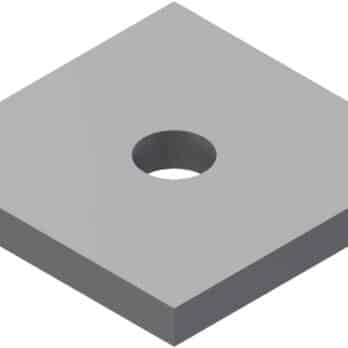

- Square Plate Washers:

Distribute loads evenly, protecting channels and ensuring secure connections.

- Right Angle Tee Brackets:

Enable perpendicular connections, providing structural support.

- Wing Brackets:

Allow adjustable connections for versatile installations.

- Threaded Rods:

Offer customizable support and suspension for components like pipes and conduits.

- Spring Nuts:

Facilitate quick and secure component attachment without drilling.

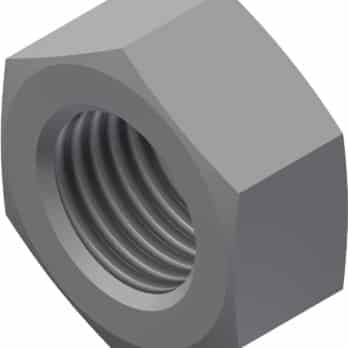

- Hex Nuts:

Provide stability by securing bolts and threaded rods in various fastening tasks.

- Double Gusseted Base Plates:

Strengthen vertical strut installations, enhancing load capacity.

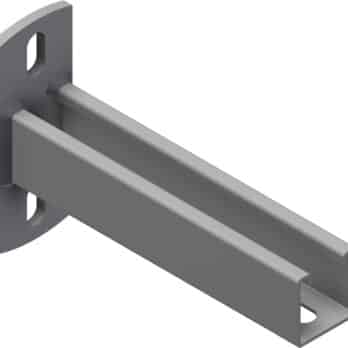

- Cantilever Arms:

Support overhanging loads, maximizing spatial efficiency for pipes, ducts, and cable trays.

Real-World Applications and Case Studies

Case Study 1: Coastal Infrastructure Project

- Challenge: Traditional materials corroded rapidly in saltwater-heavy environments.

- Solution: Stainless steel strut channels and accessories were installed.

- Outcome: The project achieved long-term structural integrity, reduced maintenance, and extended durability.

Case Study 2: Food Processing Facility

- Challenge: Cleaning agents and strict hygiene requirements caused corrosion in standard materials.

- Solution: Stainless steel strut systems were implemented.

- Outcome: The facility maintained compliance with hygiene regulations and improved the longevity of its support systems.

Key Takeaways

- Stainless steel strut channels and accessories provide unmatched corrosion resistance, strength, and hygiene benefits over HDG and pre-galvanized materials.

- They are particularly suitable for challenging environments such as marine areas, chemical plants, and industries requiring rigorous hygiene standards.

- Despite higher upfront costs, the long-term advantages of reduced maintenance and extended lifespan make stainless steel a cost-effective choice.